Craft & Cork >> Winemaking

Degassing: Removing Those Pesky Bubbles!

Have you ever wondered where the unwanted bubbles in your craft wine came from or how to get rid of them? Experienced craft winemakers may already know the various tricks for reducing bubbles to unperceivable levels in craft wine. For those who are new to craft winemaking, in this week’s Craft & Cork I will teach you everything you need to know about these bubbles, including methods for removing them. I will also provide tips to help you produce a wine that is softer and smoother on the palate.

What are the bubbles?

During primary fermentation, the yeast that you added to the juice will metabolize the sugar, therein producing CO2 (carbon dioxide) and alcohol. It is this production of carbon dioxide that results in the foam that you might see during fermentation, or when the wine is being agitated during the stirring or racking processes. Although carbon dioxide adds desirable attributes to sparkling wines, it is not desirable in finished wines that are meant to be still. It does, however, still serve a purpose during making. Since CO2 is heavier than oxygen it can be used to blanket the surface of the wine keeping oxygen at bay.

During primary fermentation, the yeast that you added to the juice will metabolize the sugar, therein producing CO2 (carbon dioxide) and alcohol. It is this production of carbon dioxide that results in the foam that you might see during fermentation, or when the wine is being agitated during the stirring or racking processes. Although carbon dioxide adds desirable attributes to sparkling wines, it is not desirable in finished wines that are meant to be still. It does, however, still serve a purpose during making. Since CO2 is heavier than oxygen it can be used to blanket the surface of the wine keeping oxygen at bay.

The amount of CO2 contained in the wine is primarily affected by the temperature at which the wine is fermented. Lower fermentation temperatures will result in more CO2 being dissolved into the wine. Therefore, if you are fermenting your white wine at 15 degrees Celsius versus 25 degrees Celsius, your wine will require more effort to remove the CO2 during the degassing process, ensuring those pesky bubbles are eliminated.

Degassing Methods

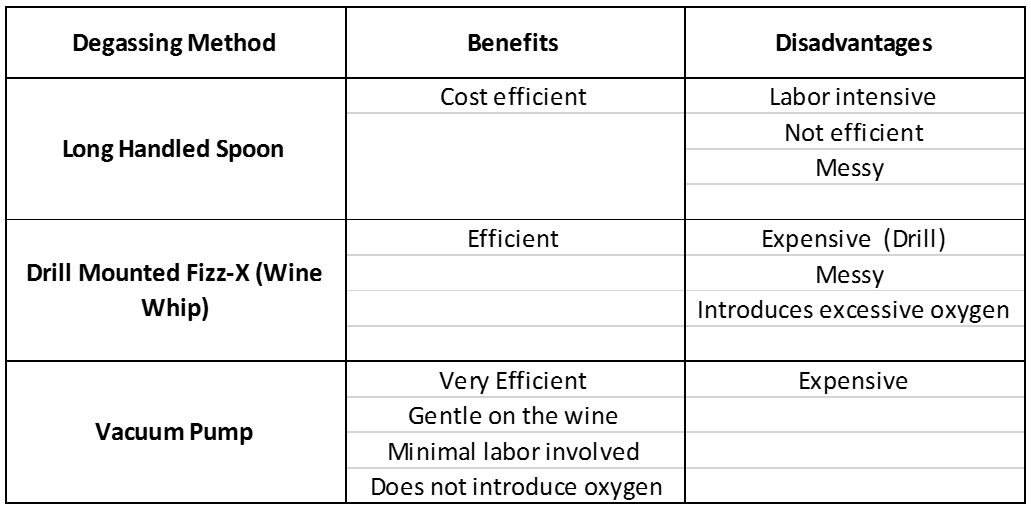

The following table highlights 3 of the most common degassing methods used to remove CO2 from the wine for craft winemakers and highlights the benefits and disadvantages of each method.

- Long handled spoon – A total time of approximately 10 minutes of stirring is required to thoroughly degas a 23L (6 US Gal) wine kit.

Drill mounted Fizz-X (wine whip) – This method requires a total degassing time of around 5 minutes and requires the use of a 12V drill as well as a wine whip which can be purchased from your local winemaking store.

Drill mounted Fizz-X (wine whip) – This method requires a total degassing time of around 5 minutes and requires the use of a 12V drill as well as a wine whip which can be purchased from your local winemaking store.- Vacuum pump – This method is by far the most efficient for removing CO2 from the wine. It requires the use of a single stage vacuum pump to create a negative pressure of around -18 PSI. By holding this negative pressure for around 3-5 minutes, all perceivable CO2 will be removed from the wine without introducing any oxygen. This will help maintain aromatic freshness and produce a wine that has a soft, round palate. It is important to note that this form of degassing can only be performed in a glass carboy and the carboy MUST be filled above the shoulders to reduce the chances of the carboy imploding.

The number of topics that can be discussed when it comes to degassing is endless, so I encourage you to post comments and questions at the end of this blog or contact me for more information on each method.

Chris Holman has been making wine professionally since 2006, which has led him to work in regions such as the Niagara Peninsula, Okanagan Valley, McLaren Vale South Australia, and Tasmania. Chris earned a 2 year diploma at Niagara College in Winemaking and Viticulture in 2008 and more recently he received a 4 year B.Sc degree majoring in Oenology and Viticulture at Brock University in 2015. His academic achievements in addition to his technical winemaking experience will allow him to provide our customers with excellent technical support and new ideas, helping them continue to make excellent wines.

Chris Holman has been making wine professionally since 2006, which has led him to work in regions such as the Niagara Peninsula, Okanagan Valley, McLaren Vale South Australia, and Tasmania. Chris earned a 2 year diploma at Niagara College in Winemaking and Viticulture in 2008 and more recently he received a 4 year B.Sc degree majoring in Oenology and Viticulture at Brock University in 2015. His academic achievements in addition to his technical winemaking experience will allow him to provide our customers with excellent technical support and new ideas, helping them continue to make excellent wines.

Comments are closed.