What equipment will you need to make your craft wine?

Carefully inspect all equipment prior to use to ensure proper functioning and integrity; look for cracks in airlocks and hoses, stains on processing equipment, and corroded metal surfaces. Make sure to retire old equipment and do not purchase used equipment, especially from unknown or unreliable sources.

Primary Fermenters

These are used for the vigorous phase of Alcoholic Fermentation.

Food-grade pails with lid:

- 30-L (8-gal) pails for 23-L (6-gal) kits will allow for volume expansion during fermentation, while minimizing risk of oxidation.

Secondary Fermenters

These are used for the less vigorous phase of alcoholic fermentation, i.e. secondary AF, and for clearing when wine is more susceptible to oxidative and microbial spoilages.

23-L (6-gal) glass carboys

- Easy to clean and maintain

- Prone to breakage and injury

23-L (6-gal) PET carboys / Better Bottle

- Polyethylene polymer

- Lighter and safer alternative to soft glass

- More prone to scoring when using stainless steel or sharp edged implements

Thermometer and Hydrometer

Thermometer

- For measuring correct juice and wine temperature prior and during fermentation.

- Thermometers are available in standard, floating or laser formats.

How to Use a Hydrometer

- Clean and sanitize hydrometer and test cylinder

- Ensure that test sample is clear of floating solids and CO2 gas, otherwise, measurements can be skewed

- To remove solids, filter sample through coffee paper filter

- To remove CO2, stir or shake sample vigorously

- Ensure that the test sample is as close to the hydrometer calibration °T

- Place hydrometer in test cylinder

- Pour sample in test cylinder and close to the top

- Spin hydrometer to remove air bubbles

- Read SG & PA at bottom of meniscus

- Return sample to batch

- Rinse hydrometer and test cylinder with clean water and store away

Hydrometer & Test Cylinder

- For measuring Specific Gravity (SG) and Potential Alcohol of juice and wine

- Important to measure samples at hydrometer calibration temperature; most are calibrated at 15.5 or 20.0°C (60 or 68°F)

- Triple scale is industry standard

- Used to ensure fermentation is complete prior to stabilization.

- Please refer to instructions for target SG

- Ensure that your hydrometer is calibrated from time to time. Fill your test cylinder with distilled water at 15.5°C or 60°F and place your hydrometer in the cylinder. The hydrometer should read 1.000. If it reads 0.998 add 0.002 to all measurements. If it reads 1.002 subtract 0.002 from all measurements.

Racking Equipment

These are used to transfer wine from primary to secondary fermenter, or from one carboy to another following clarification.

- Siphoning (food-grade) hose with flow-control clip

- Plastic racking cane (J-Tube) with lees tip

Oak barrels

Oak barrels are a great way to take your wine to the next level. For red wines, oak barrels will help to soften and round out tannins, For white wines, they will help to add weight and volume on the palate. They will contribute additional aromas such as vanilla, coconut, cedar, chocolate, baking spices, and smokiness depending on the type of barrel being used.

- French, Hungarian, American

- Sizes vary from 3.8 to 500 L (1 to 120 gal)

- Only use new or used barrels of known provenance

- Must swell with HOT water prior to initial use

- Expect wine loss due to evaporation and expansion / contraction during aging; depends on cellar temperature & humidity

- Require strict maintenance regimen to avoid wine and/or barrel spoilage

- Refer to manufacturers’ instructions for additional guidelines

- Between uses when wine is not being stored in barrel ensure that barrel is kept full with a citric acid sulfite solution. 20-30L barrel (1 TBSP Citric Acid / ½ TBSP Sulfite)

Airlocks and Bungs

Closure used to protect wine from oxidation and ambient micro-organisms.

Two types of airlocks (aka fermentation locks)

- Triple bubble

- 3-piece type

- NOTE: Fill your airlock half full with water along with 1/8 teaspoon of sulfite to prevent airborne spoilage organisms from entering the wine

Bungs

- Only use food-grade rubber or silicone bungs

- Ensure correct size is used

Follow the chart for proper use.

| Carboy Size | Sku # | Bung Size |

| Glass Carboy 23L | 20799 | 6.5 |

| Glass Carboy | 20803 | 6.5 |

| Glass Carboy | 20801 | 6.5 |

| Better Bottle Plastic | 28639 | 10 |

| Better Bottle Plastic | 26983 | 10 |

| Plastic Carboy | 24148 | 11 |

| Plastic Carboy | 23895 | 11 |

Degassing Equipment

- Used to reduce residual CO2 to an imperceptible level; some small amount is still desired for freshness and to help volatize aromas, but there should be no prickly sensation on the tongue.

- Each wine should be evaluated on a case by case basis to understand how much degassing needs to be done

- Wine that has not been sufficiently degassed will not clear properly and may have a sharp and bitter finish to it

Useful Miscellaneous Equipment

- Stirring spoon

- Wine “thief” for sampling

- Measuring spoons – ½ & 1 tsp, 1 tbsp

- Measuring cup – min. 2-cup capacity

- Small, medium & large funnels

- Spray bottle for spraying equipment with sulphite solution

- Carboy washer

Topping wine (commercial white or red equivalent). Avoid using water for topping.

Methods

Manual / spoon method:

- Stirring rod with flip paddles (e.g. Fizz X / Wine Whip) – Use with electric drill

Vacuum Degassing:

- Uses compressor or vacuum pump, bigger compressor reduces degassing time

- Can degas multiple carboys and reduces labour

- Very gentle on the wine

- Does not introduce any oxygen which helps to preserve aromatic freshness

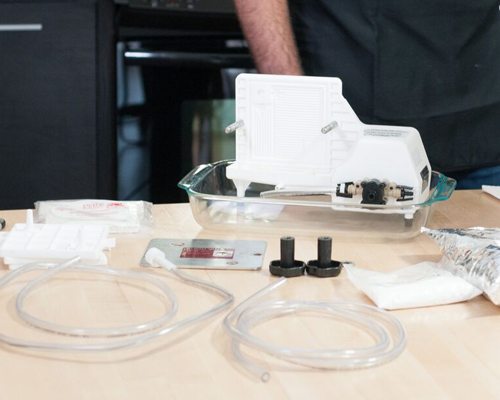

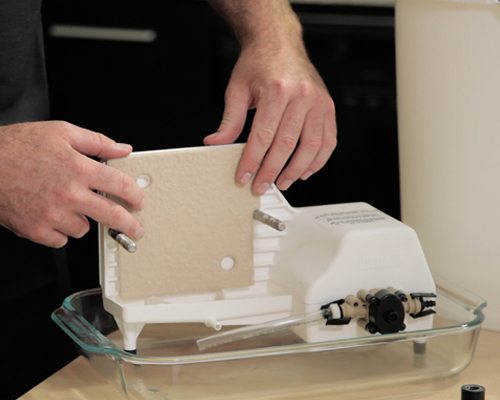

Filtration Equipment

Used to remove suspended particulate matter from wine to obtain a crystal clear finish. Wines MUST be clear prior to filtering.

- Filtering machines are a hot spot for bacterial contamination and proper cleaning process must be followed.

Buon Vino:

MiniJet (built-in pump) uses 3 “square” filter pads; rated #1 (coarse or 5 μm) to #3 (fine or 0.5 μm)

SuperJet (built-in pump) uses 3 square filter pads; rated #1 (coarse or 5 μm) to #3 (fine or 0.5 μm)

Note: Soak filter pads in 10 liters of cold water containing 3 ½ TBSP of citric acid and ½ TBSP of sulfite prior to use. This will sanitize your filter pads and will also negatively charge the pads helping to pull out more haze causing proteins from the wine. Once filter pads are installed into filter, circulate this sulphite/citric acid solution through the filter for 5 minutes. Flush with 5-10 liters of cold water.

Filter pads have a smooth side and a coarse side

- Follow manufacturer’s instructions carefully

- Wine to be filtered must flow into the coarse side

Store filter pads in their original packaging or an air tight container

Bottling Equipment

Bottle Washing / Sanitizing

- Avonator (bottle sulphite pumps) are the best way to sanitize bottles prior to use

- Allow bottles to drip dry on a bottle tree for 5-10 minutes prior to filling

- Always visually inspect each bottle prior to filling

- Modular bottle “tree” for draining cleaned/sanitized bottles

Corker

- Avoid hand corker models

- Sturdy floor corker